Shop by Category

Arrow Fixtures

Custom engineered and assembled to fit your exact specifications. Built to last with internal plumbing.

ROBUST. PRECISE. SUPERIOR.

We have designed and built custom workholding fixtures to hold aluminum and magnesium die castings, sand castings, forgings and bar stock. Our fixtures can be fully integrated into robotic cells or manually loaded on single stand-alone machines.

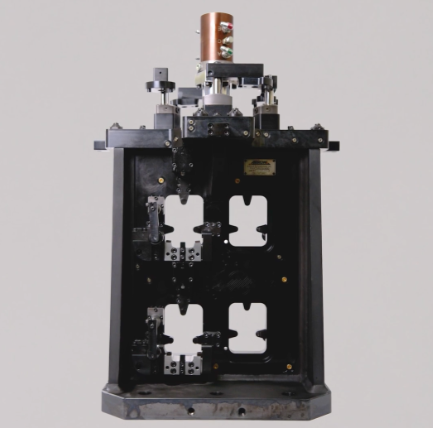

WORKHOLDING FIXTURES

Our engineers have developed innovative methods to locate, clamp and support even the most delicate parts. Every fixture we create utilizes sequencing and pressure reduction to fit your exact specifications.

PNEUMATIC WORKHOLDING

Most of our customers require fixtures to machine parts but some use our fixtures for deburring or welding. We have designed and built custom workholding fixtures for the automotive, sporting good, healthcare, energy and agriculture industries. We have designed and built custom workholding fixtures to hold aluminum and magnesium die castings, sand castings, forgings and bar stock. Our fixtures can be fully integrated into robotic cells or manually loaded on single stand-alone machine.

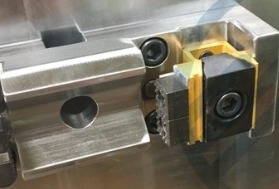

HYDRAULIC WORKHOLDING

Hydraulic fixtures designs are always created with internal plumbing. The tombstones become giant manifold blocks with a network of long gun-drilled holes that supply the clamps and work supports from inside. This eliminates the maze of steel tubing that typically surrounds a hydraulic fixture leaving a clean space for your operator and programmer to work. Fixtures that are internally plumbed, using manifold mounted components are more reliable and are easier to use and maintain.

MANUAL WORKHOLDING

Manual fixtures are ideal for heavier more rigid parts. They’re also a good option for short-run production. We have the expertise to design a simple and reliable manual workholding fixtures using robust components and superior design techniques. Utilizing a manual fixture is a cost-effective way to run lower volume parts or parts with longer cycle times. Manual fixtures can be designed to work on both horizontal or vertical machine tools.

CUSTOM GAUGING

Fixtures aren’t just used to machine parts; they’re also used to inspect parts. Quality engineers face the same problems as design engineers. Odd shaped parts are as difficult to inspect as they are to machine.

CMM FIXTURES

Inspection fixtures are used at the machine on the CMM or on the surface plate. While an inspection fixture doesn’t have to be designed to withstand the rigor of the manufacturing process it does follow the same principles of location, support, and stabilization. Like CNC machine tools on the shop floor, CMM’s are a necessity in the manufacturing process.

FUNCTIONAL GAUGING

Our team has the ability to design and build simple functional gauges to be used at the machine or in the inspection room. Functional gauges at the machine will target specific machined features making your operator the first line of defense against costly errors. Non-conforming parts are identified immediately so process can be stopped and adjusted.

QUALITY CONTROL

Planning

Quality begins up front with a detailed plan. Before a job is released to the shop, the drawings are reviewed by a team of management, engineers, and inspectors.

Quality Lab

All of our inspection equipment is maintained and subjected to regular, periodic calibration. For quality control, we utilize two Browne and Sharpe CMM’s as a means of in-process production part control and final inspection, performing repeatability and reliability checks.

ISO Certification

Every job and every customer have their own requirements. If that requirement demands a higher level of documentation, we’re prepared to deliver with ISO 9001:2015 certification standards.

Final Inspection

We’ve developed a detailed check-list to make sure that nothing is overlooked during the design and manufacturing of our fixtures and contract parts. Products don't ship if they don't pass our inspection standards.

LIGHTNING FAST RESPONSE

Quotes are typically completed within 1 week.

Average delivery usually within 12-14 weeks.

All quotes come with a concept for a visual representation.

Address

6164 All World Way

Roscoe, IL 61073

Phone

(815) 943-9111