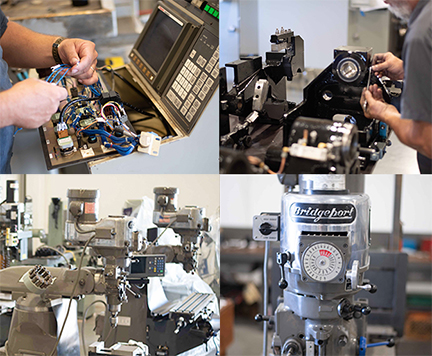

Bridgeport, Okamoto, Harig Surface Grinders, Mitsui, and Hardinge Lathe Rebuilding and Refurbishing

Over the years, manual machining equipment has taken a back seat to more advanced forms of CNC machining in order to keep up with the fast-paced, high-demand production environments of today. While manual machining processes may seem to be a thing of the past, most manufacturing facilities still utilize this equipment on a daily basis.

USA Machine Rebuilders understands that these machines were built to last. For nearly 40 years, our technicians have been rebuilding and refurbishing these quality machines to original specifications.

Now that USA Machine Rebuilders has joined with All World Machinery Supply, we have the ability to expand our services to a much larger range of customers.

Upon delivery, our team will completely disassemble your machine and all components will be thoroughly inspected. Machines will be rebuilt to factory specifications with optimal alignment and performance.

We specialize in Bridgeport, Okamoto, Harig Surface Grinders, Mitsui, and Hardinge lathes.

USA Machine Rebuilders Advantage

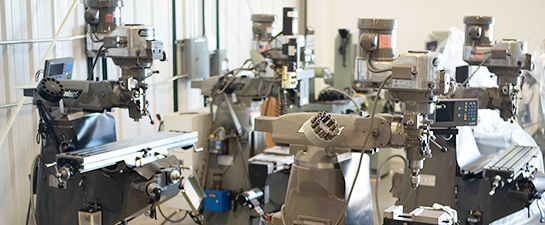

Machines for Sale

Along with rebuilding and refurbishing machines, USA Machine Rebuilders also carries a large inventory of machines for sale. These machines have been inspected, refurbished, and tested for optimal performance.

We have refurbished Mitsui, Bridgeport, Okamoto, Harig Surface Grinders, Hardinge machines, and much more.

Machines are generally guaranteed for one year, with normal use and proper maintenance.

Our 14-Step Process

- Dismantling the machine tool & disassembling all units

- Re-grinding the tabletop

- Scraping, flaking, and fitting knee column ways

- Polishing all brightwork

- Assembling and realigning the machine to its original factory tolerance

- Cleaning and inspecting all parts

- Scraping, flaking, and mastering the ways

- Replacing all gibs and lubrication system metering valves

- Inspecting and repairing the electrical system

- Custom painting the complete machine and all accessories

- Readied all components for customer inspection

- Scraping, flaking, and mastering carriage to knee ways

- Installing the new table and cross-feeding screws and nuts

- Repairing or replacing all remaining parts that may impair the machine's full efficiency

Spindle Repair Services

Through our vast network of partners and resources, All World Machinery offers solutions for all of your spindle repair needs. Our technicians are able to assist on-site with extraction and installation of your spindle so that you can get back to optimal efficiency.

Often, chiller repair and oil chiller maintenance can prevent spindle damage or failure. While your spindle repair is underway, please consider having your chiller inspected as well so that we can further assist you on finding what caused the problem.

Save up to 40% vs buying a new spindle!

Repair Services Include:

- No cost evaluation and estimate

- Regrinding of precision surfaces

- Replacement of worn components

- High-speed spindle repair services

- Updates to drive systems

Contact Us

USA Machine Rebuilders

6164 All World Way Roscoe, IL 61073

Call Us

815-943-9111