Shop by Category

ClampMAX® Accessories

Go Big Or Go Home

ClampMAX® offers a wide range of accessories for you to make the most of your hydraulic power system. From a customized HMI display to air gap packages, ClampMAX® can meet the needs of any workholding application.

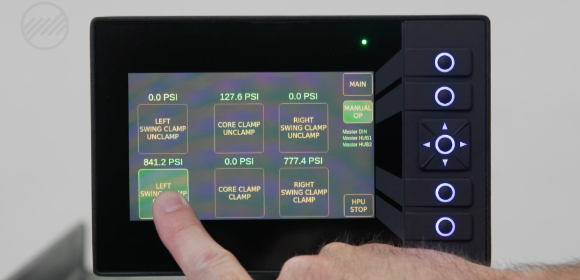

HMI DISPLAY

With the utilization of IFM PLC technology,our HMI package allows for easy monitoring of current real time condition status. This allows you to see what is actuated in real time, with the ability to make live adjustments to your pump, sensors, and switches. Always know your maintenance status with alarm display features that include alarm history, alarm descriptions, and suggested maintenance.

- Find your operation manual preloaded onto the display for easy access.

- The HMI connects to the control system with a simple ethernet IP connection using the standardized IFM smart hubs.

- Cycling the unit between step by step movements for setup and maintenance purposes or automatic modes for machine tool operation on the HMI interface can be done with a single keystroke.

- Want to operate the HMI from the PLC instead of mounting to the unit? Easily place you mount on your PLC using the standardized magnetic mount adapter and retractable cable system.

OPTOTOUCH CONTROL BAR

This ergonomic and robust two-hand control run bar with panel safety relay controls actuation while safeguarding the operator to ensure hands are out of the machine to operate them. Used in connection with the the two hand control safety modules designed into the HMI controls..jpg)

- Two sizes available. Standard size and extended size for additional selector switches and indicator lights. Extended size covers more complex operations.

- Run bars can be mounted either on our designed anchor-mounted pendant stand, or on the machine center directly. Can be configured with additional buttons and indicator lights for monitoring and correct clamping verification.

- For fixtures with manual coupling systems that need operators to couple to the fixture, an optional hanger clip feature is available. The hanger clip system has a has a sensor in it which can tell if the coupler is disconnected from the fixture and in the holder cradle before it will allow the pallet to be sent in the machine or pallet pool.

AIR GAP PACKAGE

This package is a pneumatic, high precision set-up for part seat con?rmation that checks the adhesion between the part and the ?xture, preventing machining defects and downtime.

.png)

AIR BLOW PACKAGE

Between part reloads, the part seat and part datums become compromised with dust and debris. Automatically or manually utilizes compressed air to clean your application before each reload.

LEVEL SENSOR

For the reliable point level monitoring and temperature control in tanks and containers, the IFM level sensor seamlessly detects minimum level, leakage, or over?ow of tanks.

DRIP & DRAIN PANS

These matte black pans are speci?cally made for industrial and large commercial applications. A small valve for drainage is located for easy liquid removal..

WHEEL KIT

Wheel kits make the transportation of your customized unit a breeze allowing for maximum ?exibility of placement so that you can take it anywhere safely and quickly.

COUPLING

Optional manual coupling options also available with Banner Safety Two Hand Tie down with safety relay for safe operations of pallet pools.