Oil Chiller Repair and Maintenance

The job of an oil cooler is very similar to the radiator in your car, except that we use refrigeration to cool the oil, which chills the coiling loop around the spindle housing, allowing the machines to run at faster speeds.

The reality of a spindle is that to keep the parts coming out accurately, the temperature must be maintained, and oil is a great medium for controlling heat. Often when a spindle malfunctions or needs to be repaired, your oil cooler may be a part of the problem.

While oil chillers are durable and smart, they need to be regularly maintained to ensure that they are running efficiently and correctly. If an oil chiller goes bad, the spindle will follow, and spindle repair is expensive. Oil coolers and spindles are affected by ambient temperature as well, and this could lead to problems.

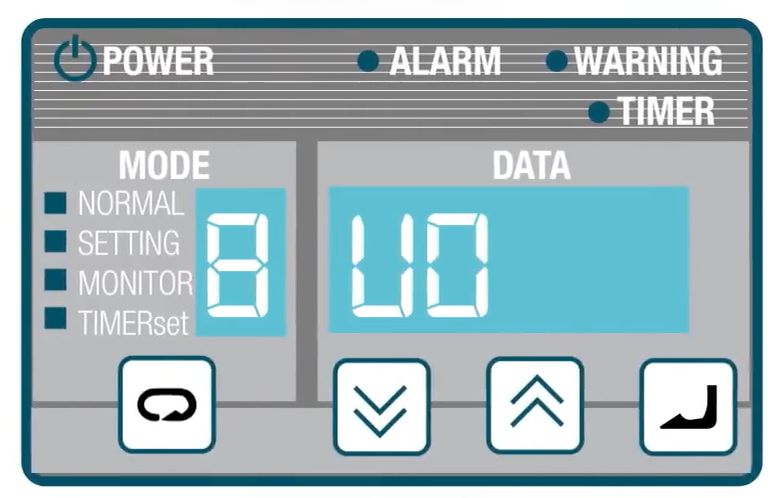

When customers call into All World, we can usually diagnose the problem over the phone. We have an extensive collection of documentation and knowledge to help you through the process. Some of the more common error codes are listed below:

Common alarm codes for Daikin oil coolers/chillers

- EH - (pump overcurrent alarm) Faulty pump or bad main board

- UO - (shortage of refrigerant) Leak in system

- U2 - (Malfunction due to power supply voltage) generally the chiller lost main power or the main control board is bad

- A6 - (DC fan stop) Fan other or main board

In the case where an oil cooler system is sent in, it is inspected and quoted for the estimated cost of repair. Once the purchase order is received the unit is scrubbed down, cleaned, and flushed. Once the components needed for the repair are changed, the unit is plugged in, run and tested, inspected again and sent back to the customer. Our goal is to create a clean bill of health for each unit that is sent to us for oil cooler maintenance and repair so that they are ready to get back to work. With the efficiency and knowledge of the team, the turnaround time for your oil cooler is usually averaged around 5-10 days upon arrival, though some turnarounds are much faster.

In some cases, the cost of the repair is equal to or close to the price of a new unit. When that happens, All World will offer an option that works as a drop-in replacement. Most replacement options are in stock and are ready to ship same day.

All World services a range of oil chiller lines of various manufacturers, makes, and models, such as Daikin oil chillers, Habor, MAC, Kanto Seiki, Panasonic, Matsushita, and other brands. We have two locations in Georgia and Illinois to better serve our customers.