What is an Actuator?

The raw definition of an actuator is that it is a mechanism that puts something into automatic action.

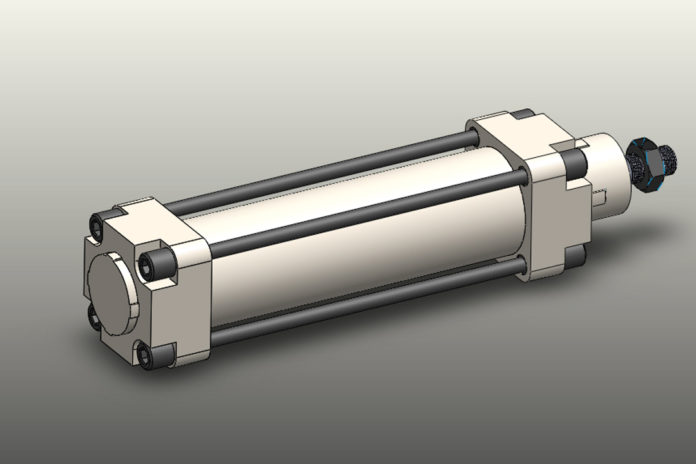

The raw definition of an actuator is that it is a mechanism that puts something into automatic action.In our line of business, the actuators we commonly come across are rotary actuators which are used on lathes, however, actuators are not limited to lathes. I will focus on the rotary type that you will come across more frequently. The rotary actuator on a lathe is the device mounted on the back end of the spindle outside of the work area. It is responsible for the holding force which closes the jaws on the chuck which holds the part being machined by the lathe.

The rotary actuator is a hydraulic cylinder on which the center shaft can move back with hydraulic force as it holds that force while the inner shaft spins. The actuator does not spin on its own but is threaded onto the spindle drawtube of the lathe. When the spindle runs, the actuator shaft spins, while the outer housing of the actuator is held in a stationary position by a bracket which is usually mounted to the frame of the lathe. There will be typically three hose lines that run to the actuator. Two lines that handle the extend and retract movements, and one line for an oil drain path. The spindle shaft they connect to is commonly called the spindle draw tube and it goes through the center of the spindle and connects to the back of the chuck. The actuator extending and retracting action controls the jaws of the chuck of which the body of the chuck is mounted to the spindle. This motion causes the jaws to either move in or to move outward. The jaws are typically designed so you can move them in to clamp on the outside of a part, or to move them out to clamp a hollow part from the inside.

I mentioned a drain line earlier. This drain line is usually a larger clear inner braided hose so you can visually see the oil flow down and it typically runs to a drain port on your hydraulic system which controls the actuator. I mention that because there are many times when people call for hydraulic units but don’t need a hydraulic unit. They think they do because they may have a bad leak in the actuator. You see, the actuator is meant to allow some oil flow over the bearings to allow free movement at high speeds. This oil cools and lubricates the moving parts allowing the outside to be stationary while the inside can spin at 5,000 rpm, as an example. When you have seal failures in the actuator the oil trickle becomes a large flow of oil. When this occurs the pump may run hot or may lose holding force on the chuck as an example. So this will appear as a hydraulic unit failure but is not. You will need to advise them of what they should check first.

So when you have someone ask you about a hydraulic unit, because they think that they have a failure, you need to ask if it is a lathe and then ask if they checked to see if they have a large leakage from the actuator. If you don’t do this, and they put a new pump on that they bought from you and it does not work, then they will lose confidence in your knowledge of the products. So, always try to advise the customer and help them to learn from you. If you do this, then they will trust that you are knowledgeable and will feel more comfortable calling again to help them solve future problems that come up. Now you should have some idea of what a rotary actuator is on a lathe and how it pertains to you.

Written By: Darrell Janesak, Senior Technology Advisor

Please contact Darrell for more information at 1 (815) 943-9111

Tags

daikin

oil

hydraulics

awm

cnc

machine

lubrication

azbil

hydraulic

coolant

ehu

ecorich

sensors

repair

service

tool

pressure

application

pump

maintenance

tank

machine tool

grease

how to

cnc lathes

machinery

manual

parts

workholding

fixtures

custom

energy

pneumatic

technology

clamping

filter

mpa

psi

replace

fix

sut

motor

hpu

eco rich

iot

corepull

ClampMAX

HPU

Daikin

SUT

EcoRich

Eco Rich

Pallet

Clamping

Workholding

IFM

Clamp

Fixtures

IOT

Industry 4.0

Custom

Application

Solutions

flow

output

voltage

accessories

how to install

Hydraulic Units

Hydraulic Products and Systems

oil mist

proximity switches

machine rebuild

patlite

okamoto

grinder

grinders

titan

sales

rebuild

retrofit

spindle

engineering

technician

aerolap

nc

ca1

ca2

caiq

dx

dxnc

iq

ogm

ncag

udbx

uiii

unciiim chnc

chiq

igm

15nc

15nciii

2mb

gx

sa1

column

surface

type

cylindrical

double

id

rotary

saddle

linear

acc

upz

ball bar

laser

calibration

installation

extraction

tools

automotive

sporting good

healthcare

robots

agriculture

aluminum

magnesium

robotic

castings

forgings

bar stock

cells

tombstone

manifold

design

horizontal

vertical

cmm

inspection

customer

support

machining

process

axis

clamps

contract

chucks

live

tooling

iso

fastener

filtration

mesh

micron

element

canister

inline

head

direction

fluid

inlet

outlet

build up

plugged

replacment

suction

strainer

paper

media

discharge

return

water

rating

viscosity

spin on

line

indicator

pm

preventative

housing

stainless steel

wire

body

skimmer

tramp

overflow

absorbants

rags

belt

removal

bacteria

chips

fines

buildup

skim

clean

waste

hybrid

valve

chiller

cooler

troubleshoot

alarm

code

keypad

akz

akj

akw

akc

system

all world

heat

stock

noise

efficient

savings

adjustment

clampmax

pallet

ifm

clamp

industry 40

solutions

fixture

piston

fill

prime

power

lube

slr

progressive block

pdi

single line

resistance

positive displacement

injector

failure

replacement

lube usa

showa

graco

lincoln

daido

skf

vogel

taco

aryung

hansung

bijur delimon

greasing

greasing a bearing

mistakes to avoid

grease gun

grease syringe

grease application

SUT hydraulic unit

SUT Hybrid Power Units

EHU hydraulic unit

Eco-Rich EHU Hybrid Power Units

hydraulic power solution

multi-pallet system

panel builds

coolant mist

preventative maintenance check

Troubleshooting

Trochoid Pumps

Gerotor Pumps

usa machine rebuilders

refurbished machines

machine rebuilds

machines for sale

CKD

new website

instructions

miracle boy

ckd

welding

safety glass

machine retrofit

bohle flutemaster

newall troublshoot

signal tower monitoring

wd72

orings

pressure settings

energy efficiency

omron

marposs

metrol

nachi

bearings

limit switches

bando wiper edge

preventative maintenance

coolant pump

injection molding machines

oil chillers

oil chiller repair

linear motion guide

kyodo yushi

photoelectric sensors

daito

fuse

actuator

Show All

Posts

2024

March

2023

Unmatched Grinding Accuracy Plus Machine and Parts Availability

[03/27/24 08:54 AM]

Arrow Workholding Fixtures

[03/06/24 06:47 AM]

February

The Right Filtration for Your Machine Tool Application

[02/20/24 10:08 AM]

Oil Skimming Solutions for Machine Tools

[02/07/24 08:11 AM]

January

September

August

2022

ClampMAX Case Study for Industrial Bearing Manufacturer

[08/28/23 03:05 PM]

ClampMAX Case Study for Additive Manufacturer

[08/28/23 03:05 PM]

June

How to Prime a Piston Pump

[06/30/23 02:17 PM]

Choosing the Right Lubrication Pump

[06/30/23 02:17 PM]

May

October

2021

2020

How to: Install SUT Hydraulic Unit

[10/06/22 03:01 PM]

How to: Install EHU Hydraulic Unit

[10/06/22 03:01 PM]

September

ClampMAX Case Study for Multi-Pallet System

[09/02/22 12:06 PM]

Preventative Maintenance Check: Oil Mist

[09/02/22 09:09 AM]

August

March

December

November

October

2019

Patlite Product Highlights

[10/23/20 09:00 AM]

Product Spotlight: CKD Nitrogen Extraction Unit

[10/13/20 03:04 PM]

September

August

May

February

December

October

2018

IZUMI Friction Welding Machines

[10/29/19 10:00 AM]

AWM Machine Rebuild/Refurbishing/Retrofitting

[10/11/19 10:00 AM]

August

Eco-Rich Hybrid Hydraulic Unit (EHU & UEHU)

[08/26/19 10:00 AM]

[08/19/19 03:47 PM]

Machine Tool Safety Glass

[08/05/19 10:00 AM]

May

March

January

November

October

September

2017

2016

Troubleshooting Newall Digital Readout Systems

[09/25/18 10:00 AM]

Newall A50, C80, C70, DP700 Troubleshoot

[09/25/18 10:00 AM]

Lubrication: Grease vs. Oil

[09/25/18 10:00 AM]

Troubleshooting Daikin Oil Chillers

[09/10/18 10:00 AM]

Troubleshooting a Daikin EHU Eco-Rich Unit

[09/10/18 10:00 AM]

PATLITE Products

[09/04/18 10:00 AM]

August

PATLITE WD-Z2 Wireless Signal Tower Monitoring

[08/23/18 10:00 AM]

[08/13/18 10:00 AM]

Pressure Settings for EHU2507-40-N-903

[08/09/18 10:00 AM]

Pressure Settings for EHU3007-40-N-902

[08/09/18 10:00 AM]

July

Pressure Settings Procedure for UEHU25-M07-1530-V

[07/11/18 10:00 AM]

LHL Hybrid Lubrication System

[07/09/18 10:00 AM]

June

May

Sensors for CNC Lathes

[05/30/18 10:00 AM]

Customer Service Matters

[05/23/18 10:00 AM]

Daikin IOT Ready Hybrid Hydraulics

[05/21/18 10:00 AM]

Super Precision Ball Screw Bearings

[05/09/18 10:00 AM]

Azbil FL7M Proximity Switches

[05/08/18 10:00 AM]

Understanding the Functions of a Limit Switch

[05/08/18 10:00 AM]

April

March

[03/27/18 10:00 AM]

Hydraulics for Injection Molding Machines

[03/07/18 10:00 AM]

Oil Chiller Repair and Maintenance

[03/05/18 10:00 AM]

January