Miracle Boy Oil Filtration

Oil Filtration for the 21st Century

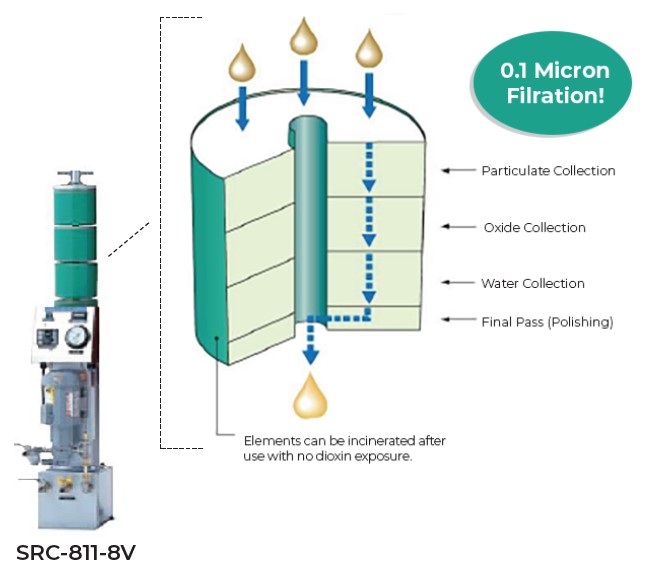

The Miracle Boy is an off-line, circulating hydraulic oil refreshing unit that is capable of removing harmful contaminants from your facility's hydraulic oil systems. Miracle Boy's filtration cartridges offer unparalleled performance and allow for sub-micron particulate filtration, reaching as far as 0.I µm. This filtration is also designed to eliminate water and sludge and is rated for nearly any viscosity oil.

Miracle Boy setup is quick & easy and in most cases requires little to no interruption of the machine's operation. The connections to and from the Miracle Boy unit can be specified in either NPT or PT style fittings. So, no matter your situation this will allow for a trouble-free installation. Built-in manual shut-off valves allow for ease of maintenance and cartridge replacement.

How can Miracle Boy save my company money?

Stop Unnecessary Component Wear: Miracle Boy removes particulate, moisture and sludge. It even lowers oxides to levels so low that machine failure due to oil contamination is non-existent.

Reduce Maintenance Requirements: Reduced component wear slows the introduction of new contaminants and therefore increases overall fluid health.

Minimize Oil Replacement: Continuous oil filtration makes oil changes a thing of the past.

Increase Efficiency and Productivity: By increasing oil health, machine efficiency is improved, resulting in higher production output and fewer stoppages.

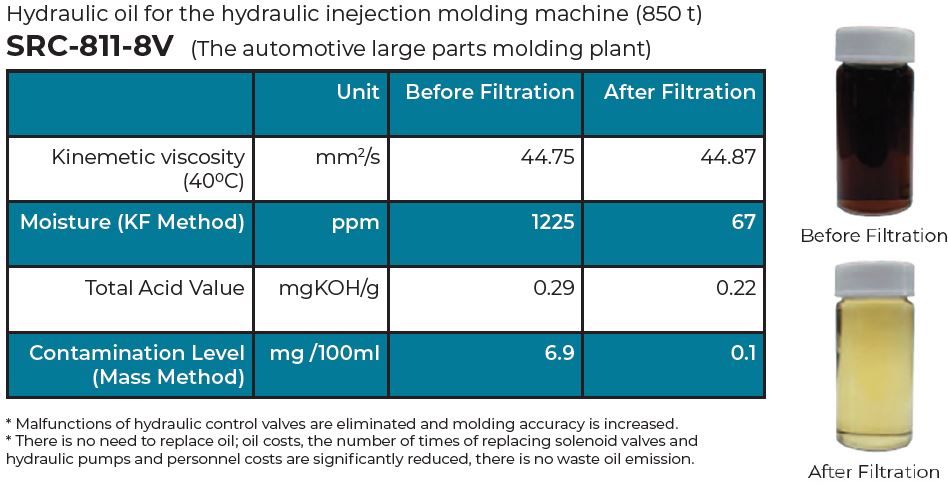

Toshiba-Machine Case Study

Toshiba-Machine installed a Miracle Boy unit to a plastic injection molding machine that produces plastic interior parts for passenger cars to improve quality and prevent failure. Miracle Boy has many advantages to the costs and labor of changing lubricant oil.

- Preserves oil quality indefinitely, keeping it just like new

- Drastically reduces machine breakdown and maintenance work

- Sharp drop in maintenance costs since, oil change and oil disposal are no longer required

- Environmentally friendly

- Prolongs equipment life drastically

- Enhances the precision/quality of products due to cleanliness of oil during operation

- Increase energy-savings

Toshiba-Machine was thoroughly impressed with the results yielded from implementing the Miracle Boy unit. They have plans to install Miracle Boy units on all plastic molding machines in the near future.

| Problem | Solution | Result | Feedback |

| Equipment oil filtration unit problem. If the capability of the machine is not 100%, it cannot meet the quality requirement level which increases year by year. | Installed Miracle Boy to hydraulic oil tank of injection modeling machine | After Miracle Boy had been installed on a plastic injection mold machine at a chemical plant, inspectors were pleasantly surprised to see a significant reduction of contaminants in the hydraulic oil while maintaining proper viscosity and color. | Plastic injection molding machine with Miracle Boy installed:

|

PDF Downloads

Aluminium Die Casting Case Study

For more information on Miracle Boy please contact your local All World representative or our main offices at 815.943.9111.