Small Shavings = Big Problems

Even at the smallest level, having the right parts for the job ensures longer life and sustainability for your investment. With Bando’s Wiper Edge Ex series, you can count on your machine is protected no matter the manufacturing process.

Keeping foreign material off your guideways ensures a more accurate and long-lasting machine. The Wiper Edge EX blades are made with a special polyurethane and designed specifically to protect way surfaces or machine slideways from dust, dirt, chips, oils, coolants, sparks and other abrasives.

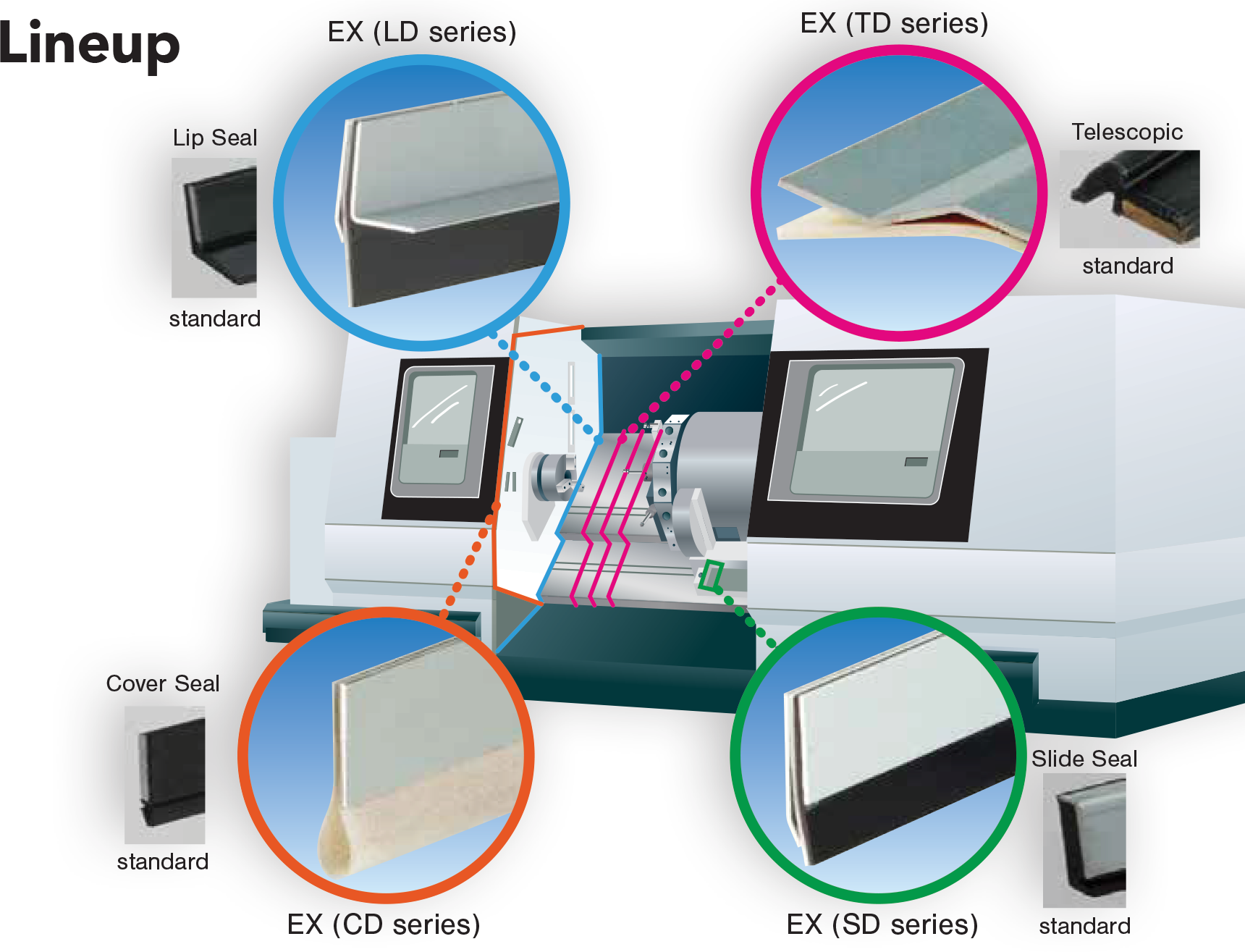

The BANDO Wiper Edge EX comes in 4 different models:

- Cover Seal (EX CD Series)

- Lip Seal (EX LD Series)

- Teleasco Seal (EX TD Series)

- Slide Seal (EX SD Series)

The unique features of Wiper EX decrease the possibility of machine stoppage due to the leakage of coolant. No abnormal noise by coolant and abrasion resistance is made leading to a quieter operational process. You can also expect a longer life for the motor from coolant resistance. Worried that the Wiper EX will not be able to perform to your machine’s high standards? The Wiper EX’s abrasion-resistant build is capable of high-speed sliding and can conform to the toughest applications instead of the other way around.