Pressure Settings Procedure for UEHU25-M07-1530-V

UEHU25-M07-1530-V

Items needed to set Eco-Rich

- Screwdriver

- Wrench

The following steps must be completed before any settings and adjustments can be made to your Eco-Rich U-EHU25-M07-15-30-V:

1. Connect 3 phase power (200 VAC ~ 230 VAC)

2. Fill oil reservoir to correct oil level. (Oil Weight ISO32 ~ ISO 68)

3. Remove transport stabilizing bolts, located next to the motor isolators.

4. Connect pressure and return lines.

5. Connect alarm wires from machine (most machines do not require this step).

6. Turn power on to machine and hydraulic unit.

7. Make sure machine is in a standby state and is not actuating any valves or cylinders.

Initial Procedures

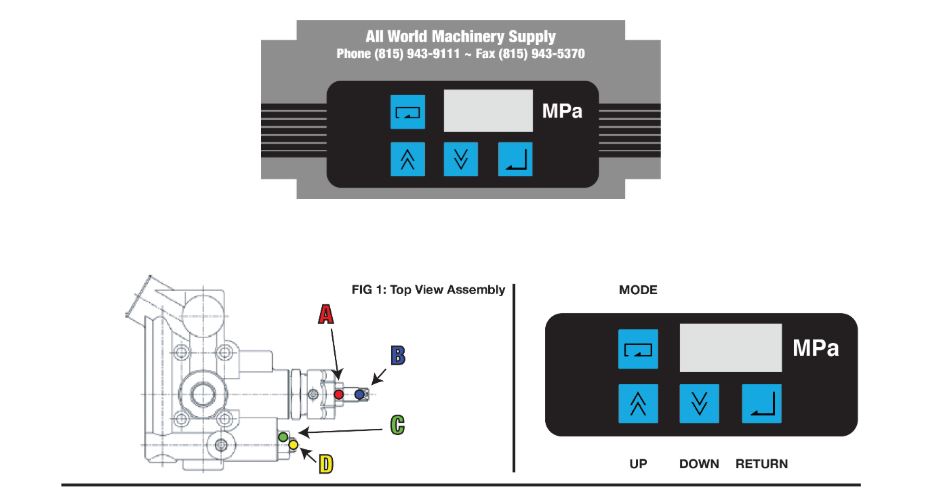

1. Break locknut “A” free, using a crescent wrench. Turn the over pressure adjustment valve “B” clockwise until the adjuster bottoms out, making sure that locknut “A” is not preventing you from bottoming out the over pressure valve.

2. On the control panel, press the “mode” and “return” keys simultaneously and hold them for 2 seconds to get you into the parameter mode. You should see "P00" flashing on the screen. "P00" is the pressure setting parameter.

3. Press the “return” key, in order to see the current pressure setting (1.5 MPa is preset from the factory).

4. To set your desired pressure, press “up” or “”down” key (acceptable pressure range is 1.5 MPa ~ 7.0 MPa).

5. Once you set desired pressure, push the “return” key. You will then see "P00" flashing again.

6. Press the “mode” key and the screen should now show your desired pressure setting.

Setting the Motor RPM

1. Press the “mode” key to get into monitor mode. You should see the “N00” flashing on the screen.

2. Use the “up” or “down” key and scroll to “N05”. Press the “return” key. On the control panel, you will see your motor RPM represented by a 2 or 3 digit number on the screen. Please note that for the motor RPM, the last digit is dropped from the control panel screen. For example, if the screen shows “122” add a zero to the end of it to get the RPM. In this case it would be 1220 RPM.

3. Loosen locknut “C” free.

4. Take a flathead screwdriver and adjust flow control valve “D”. Slowly turn the flow control valve “D” clockwise to lower and counter clockwise to raise until the motor RPM on the control panel shows 38, which is 380 RPM.

5. Lock the “C” locknut down. The motor RPM is now set.Setting the Over Pressure

Setting the Over Pressure Valve

1. With the motor RPM shown on the control panel screen, take a crescent wrench and slowly turn the over pressure valve adjustment “B” counterclockwise until you see the motor RPM start to rise above your setting of 38 (380 RPM).

2. Stop turning once you see the RPM raise and go back to the setting just before the breaking point where the motor RPM raised above 38.

3. Turn the over pressure valve adjustment “B” 3/4 of a revolution turn clockwise. Please note that if the over pressure valve adjustment “B” bottoms out before you can turn the adjustment 3/4 of a revolution turn, then take the distance that you can turn it until it bottoms out and divide it by half. This is the amount that is needed to turn the over pressure valve “B” back in clockwise. Please do not leave the over pressure valve bottomed out, as it will lead it not to operate.

4. Lock the locknut “A” down.

5. Press the “mode” key. This will bring you back to your desired pressure setting where you started.

Congratulations. Your machine is now ready to run!

Please call 1 (815) 943-9111 or email customerservice@allworldmachinery.com for more questions.